Huge Paucity in the Supply Chain of Shipping Containers

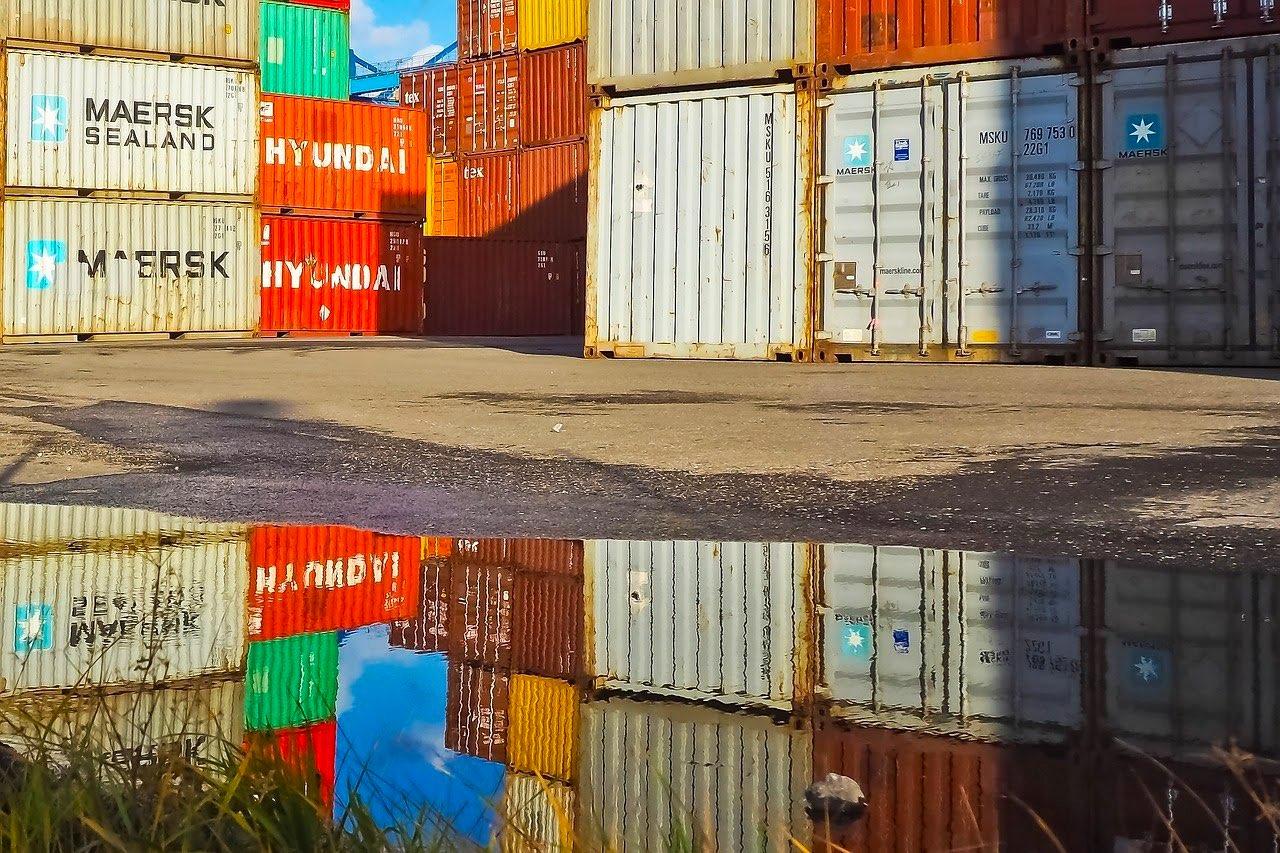

Goods are best protected by shipping containers. This is due to the fact that a container is entirely sealed once all the products are loaded into it. This keeps foreign commodities out of the container, which is especially important if the contents are raw materials or food. It is a successful means of keeping product quality even under adverse weather conditions, as well as a method of protecting cargo from extreme temperatures, theft, and other risks while in transit. Most containers are built with strong, long-lasting metal frames to keep their contents safe from corrosion, loss, and theft. Having such qualities have made shipping containers of such importance in the logistics industry. Let’s see how the shortage of these cardinal containers led to such a havoc in the logistics industry.

What led to this situation?

The unanticipated pandemic situation has resulted in a scarcity of shipping containers. When the virus struck, global lockdowns were instituted, halting output and therefore stifling economic progress. Because there were no products to ship, numerous containers were left unattended on the ports when production ceased. Shipping companies curtailed their cargo ships, and the non-collection of empty cargo containers contributed to the scarcity scenario. Finally, once the pandemic situation was under control, countries opened their international borders for trade, and demand for items that were imported and exported began to rise. Although the production of these imported as well as exported goods was slowly getting back on track, the supply was being hampered due to the shortage of containers.

Side effects of the aforementioned scenario

Because many of the containers are languishing at inland ports and the others are being used in shipping, the freight prices and workforce are suffering. Since there is a tremendous demand for containers, freight rates are increasing, and many major businesses want a piece of this historic surge in freight charges, therefore they are banding together to establish cartels. Even if the shipping container shortfall is resolved, there may be a personnel shortage. Due to the global shutdown, all ports were closed and the workforce was not permitted to work in accordance with the Covid-19 standards. A sizeable portion of this labour is employed on a daily basis, and as a result of the rapid outbreak of coronavirus, they had to stop. Many of them returned to their hometown and the remaining ones switched jobs. Now because of this situation, there is a risk of a shortage of the workforce as well.

Shipping containers abandoned in the inland ports

Impact on India

In July 2021, the monthly value of $35.2 billion was the highest in the country's history. However, due to the shortage of shipping containers and rising freight charges, this increase has been slowed down. Freight rates from Mundra to New York were $1300 for a 20ft container and $1600 for a 40ft container in March 2020; now they are $9000 for a 20ft container and $12000 for a 40ft container, and the charges from Cochin to Tokyo were $225 for a 20ft container and $550 for a 40ft container; now they are $750 for a 20ft container and $1400 for a 40ft container. Low-value export commodities such as granite tiles, tea, rice, and furniture have been hampered by these sudden rise in freight rates because they are transported in large quantities while diamonds and jewellery, chemicals, smartphones, and other consumer goods are transported by air cargo.

Impact on Logistics Industry

There is a shortage of shipping containers, and those that are being utilised are taking longer than usual because they must be used fast due to high demand. Because of the chaos, logistics companies must be more efficient and precise. The cost of shipping has also risen because the fleet is ample, but due to the paucity of containers, logistics businesses are charging the equivalent of 2-3 consignments because they must produce equal revenue through one shipment in order to ensure their recurring expenditures.

Predicting such market demand and decline is hard for humans, so the logistics industry needs to employ Artificial Intelligence, which can foresee such market demand with the use of IoT and execute data-driven decisions based on massive data lakes, as a solution for this type of crunching circumstance. CargoFL assists you with its AI software in the form of CargoFL Transport Management System, which makes data-driven judgments and provides you with the best and the most optimal results possible. Since there is a huge supply of trucks but a short supply of containers, it will assist you with fleet management by providing you with the most optimised routes, cost analysis, vehicle maintenance warnings, driver performance, and real-time tracking to aid you towards a better business growth.

Know more about this AI driven suite of logistics by getting in touch with us on +91 83290 83054 and book a demo today! You can also write to us at connect@cargo.com and we can take things further..